An organization cannot shy away from the importance of inventory management. Through inventory management, organizations control the stock, thus minimizing costs and maximizing profits and efficiency. It can be brought forth to tracking and assurance against losses and a viable supply chain. A proper inventory management system is used to overcome issues, including overstocking, stockouts, or even the loss of finances in a moving business.

For instance, in today’s business world, the invention process at an organized inventory requires all aspects of client satisfaction and the company’s profitability. Indeed, this holds for most industries, including retail and manufacturing. It observes the levels of stocks, sales, and purchases to ensure that inventory is always available. Properly organized inventory systems help businesses save on losses, reduce costs, and increase efficiency.

What is Inventory Management System?

It is either a software or a method that helps to track stock in businesses. It ensures that goods are ordered, stored, and used orderly. A well-built system of inventory management means efficiency and fewer losses. They help the business with stock status, sales, and purchasing processes. A good inventory management program can save money and prevent the organization from running out of essential products.

Most modern businesses use automated inventory management systems that automatically keep track of stock, reducing manual errors and improving accuracy. A company could view all its inventory units spread across different locations using advanced tracking tools.

Example of Inventory Management System

Retail stores for different types of clothing require proper inventory management. One way of managing this inventory is through employing a system that monitors stocks, summarizes received and viewed products, and analyzes trends in sales. So, for instance, when a particular shirt is received and it’s selling so well that store stock will deplete, the store’s system will warn the store to reorder before it runs dry.

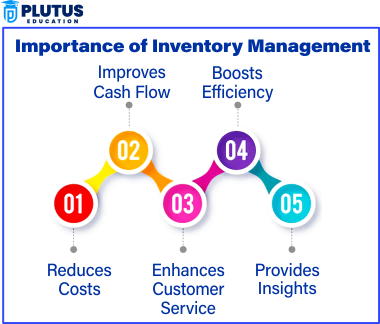

Importance of an Inventory Management System

Inventory management plays a vital role in the optimization of any business process. A business should have just the correct amount of stock concerning time. Unorganized inventory management leads to losses and diminishing profits.

Reduces Cost and Maximizes Profit

Therefore, losses hitting a business are due to overstocking or understocking of products. Overstocks accrue storage costs, while understocks typically carry costs by lost sales. Proper inventory management allows a business to control wasteful activity better while raising profit. Companies can then purchase optimally, ordering only what will eventually be needed to avoid lock-in capital for any extended period. This way, costs are reduced first by reducing holding costs on the inventory and any losses that might arise from obsolescence or expiry.

Stave Off Stock Shortages and Overstock

With the requirements that inventory management commands, stock levels will be kept on par with demand. Undernourished stock loses customers, while with an oversupply, there are excess costs, both of which can be managed with an intelligent inventory inquiry. This involves efficiently forecasting demand and taking stock levels to align with that forecast. In tandem, those two operations discourage stockpiling and remove the entertainable possibility of the customer leaving empty-handed because the required products became unavailable.

Efficiency in the Supply Chain

Good inventory management makes for an uninterrupted supply chain. Tracking of goods from supplier to customer adds to more efficiency, lesser delays in delivery, and more assurance that products get where they move on. This facilitates the movement of goods from procurement to the point of sale. Good inventory management entails coordination with suppliers at every step and decreases replenishment lead time as orders arrive.

Increase in customer satisfaction

Business houses apply different techniques for inventory control. Inventory management systems can be automated by modern technologies using software for better performance. Stock inventory management software helps eliminate manual workloads when managing stocks.

Better Financial Management

The inventory is a similar investment for every economy. Efficient inventory management minimizes waste and exerts good cash flow. Enterprises with improved inventory management avoid tying too much capital stocked for short sales. This, too, would allow for better allocation of financial resources within other areas such as marketing, expansion, or research and development.

Prevention of Waste and Spoiling

For example, businesses with perishable goods need good inventory management in food and pharmaceuticals to minimize wastage and spoilage. FIFO (First-In-First-Out) techniques ensure that older stock gets pulled off first to keep the expired or spoiled products from causing financial loss. Adequate inventory rotation keeps the quality of the products fresh.

Compliance with Regulations

Inventory accounting is necessary for the many industries in which these regulations type amounts for the inventory they keep, how long those products last, and safety measures. Good inventory management, referring to maintaining accurate records and establishing standards for the quality and safety of the products before their deployment, helps a business comply with these regulations. By doing this, many companies will avoid the repercussions of legal issues or fines and damage their reputation.

Increased Operational Productivity

Good master inventory management ensures better overall productivity for the business. It minimizes unduly wasted time on stock-related activities and allows employees to do other critical tasks in the industry. When stock is organized properly and effectively tracked, employees can quickly find the product and process the order without waiting long.

Stock Inventory Management Software

Stock inventory management software helps organizations track and manage inventory stocks most efficiently. These tools enable stock automation and improve productivity by reducing manual recording and enhancing accuracy.

- Track stock levels in real time.

- Reordering automation.

- Inventory trend reports generation.

- Lower error in stock tracking.

- Improved productivity in warehouse management.

Inventory Management Techniques

An efficient inventory system reduces costs and prevents shortfalls, which, in turn, improves customer satisfaction. Companies have drawn several inventory management techniques to maintain stock properly at different positions. The objectives in inventory management are all intended to see business supply and demand match one another without overstocking or running out of key products.

Just-in-Time Inventory

This inventory method minimizes storage costs by collecting stocks only when needed. Wastes are minimized, but demand forecasting must be tremendously accurate. Inventory is well laid out to ensure better cash flow. Positive cash flow can be invested in marketing, expansion, and product perfection.

ABC Analysis

ABC analysis separates the inventory stocks into three aspects:

A: High-value items with low sales volume.

B: Medium value and moderate sales.

C: Low-value items with high sales volumes.

Concerning the application of ABC analysis, priorities are set for action on inventory management.

First-in, First-out (FIFO)

FIFO states that older stock will sell before newer stock, keeping waste caused by spoilage to a minimum. Stabilizing flow and minimizing disruptions is possible through reducing lead time for a company in stock.

Last In, First Out (LIFO)

The LIFO method recognizes that the most recent units purchased will be the first quoted for sale. Last In, First Out is used in price increase situations because of lower taxable income. This way, the store can adequately manage stock levels, prevent wastages, and have better profitability.

Economic Order Quantity (EOQ)

The EOQ represents the order size that would minimize the costs of ordering and storing an item. It is that point at which ordering costs equal carrying costs. Managing cash flows correctly gives a business financial stability and flexibility in operation.

What is Lead Time in Inventory Management?

Lead time is counted from when the purchase order has been placed until the stock accedes. It is, therefore, important to watch over the same because it prevents a company from having stock shortages.

- Supplier processing time

- Shipping time

- Order Quantity

- Customs and regulation delays

Applications for Managing Inventory

Applications are specific to managing inventory while on the move. They all seek to attain real-time data management and automated inventory tracking. Other typical features of inventory management applications are:

- Barcode scanning

- Stock level alerts

- Linkage with sales systems

- Cloud access

- Automated order fulfillment

Importance of Inventory Management FAQs

1. What is inventory management system?

It is an inventory management system that helps businesses track, control, and manage their stock more efficiently, ensuring the right amount of inventory is available at the right time.

2. What are the different techniques of inventory management?

Different techniques of inventory management include Just-in-Time (JIT), Economic Order Quantity (EOQ), FIFO, ABC analysis, and safety stock management.

3. What is the lead time in inventory management?

Lead time refers to the time that elapses while a site waits for stock because of an order placed. It includes supplier processing, shipping, and inventory handling time.

4. What are the objectives of inventory management?

The objective of inventory management would be to minimize costs associated with it, prevent stockouts, ensure availability of products at all times, simplify order management and improve customer satisfaction.

5. What is stock inventory management software?

Stock inventory management software automates inventory tracking, reduces errors, and increases productivity.