The term “inventory management” within the business domain involves supervision and control concerning the precursor materials, components, and finished products. These goods can be of various forms, whether raw, components, or finished products. Businesses use inventory management systems to maintain the right inventory balance: not too much to incur high holding costs and not too little to miss sales. It is a fundamental goal to manage inventory so effectively that it improves cash flow, boosts profitability, and ensures smooth production and delivery cycles. Proper inventory management lets one avoid stockouts and overstocking and ensures true order fulfillment and on-time production. Strategic inventory management is a successful practice in the competitive marketplace, against most businesses that pursue it.

What is Inventory Management?

Inventory management pertains to taking order flows, storing, using, and selling a company’s inventory. This ranges from raw materials, components, and even finished products. It is one of the most essential elements in a company’s supply chain. There should be sufficient stock, not too much or too little, at the right time for the business. It also prevents stockouts and minimizes storage costs, allowing goods to move smoothly. Barcoding, SKU, and software tools will be an effective blend to control tracking and management of replenishment or consumption of stock. Inventory is the backbone of any business- the tie between production and sales. When poorly managed, excess stock or insufficient stock can hinder cash flows. In a well-managed inventory system, it boosts efficiency as customer orders are fulfilled on time while controlling cost and wastage.

How Does Inventory Management Work?

Inventory management encompasses everything from the proper warehousing of products to getting audits done; it provides all-around, meticulous procedures about having the correct number of products available in the correct quantity at the right time, so that they can avoid dead stock. No part of the process can expect anything less than accuracy, efficiency improvement, and profitability. In simple words, inventory management maintains a rapid chain of tracking goods and collaborating with suppliers.

1. Tracking and Monitoring Stock

The first activity in inventory management is monitoring stock levels through bar codes, SKU markings, or RFID scanners. Every item is assigned a unique identifier, permitting the easy movement of products in purchases, sales, or transfers. Businesses have real-time inventory management software that updates stock levels within warehouses and sales channels. Therefore, stock surveillance is done thoroughly, and many potential errors leading to stockouts or over-replenishments are avoided. The real-time visibility of stock also enhances warehouse layout design and order accuracy.

2. Demand Forecasting

Demand forecasting signals companies how their sales will likely be conceived in the future and the amount of stock that should be maintained. The step involves valuating historical sales data, real-time pulses from the market, and seasonal and promotional tendencies. Demand forecasting will thus eliminate undesired stock levels that may cause unfulfilled sales or inventory tie-in cost. For that reason, a good majority of corporations have already established either ERP systems or analytical tools based on AI that help considerably in refining that forecast. Better forecasting renders lean inventories, better rewards for wiser purchase decisions.

3. Reordering and Restocking

The reordering movement provides the safeguard that, from a threshold predetermined to end the reorder activity, the total stock will fall below that limit. This includes setting up reorder points and determining reorder quantities, which will be done by Economic Order Quantity, using methods such as EOQ. Now, some are using automated systems to send purchase orders from suppliers when the stock level falls below a minimum value. Service level assurance and fewer lost sales can then be ensured with effective reordering practice. Maintaining a fluid supply chain and consistently fulfilling customer demand will always depend on such replenishment lead times.

4. Storage and Warehousing

After receiving the delivery of an inventory from the suppliers, the next step is to store it. The organization must place the goods on shelves or bins according to SKU codes, type ofsproduct,, or rank-based popularity. Warehouse management deals with temperature controls, space optimization, and various types of security to avert damage to goods or losses. Layouts streamline functioning, such as picking and packing, and order fulfillment. Labeling and categorizing items will significantly reduce human error, providing speedy access to audits or retrieving goods for shipping.

5. Supplier and Supply Chain Coordination

The supplier cuts across smooth restocking of products,andt no time gap interrupts. This includes large-scale communications with suppliers, instructions about lead times, and keeping performance records, among other things. Reducing single source dependency increases flexibility and gives room to make choices wheneededbe in sourcing. Companies should consider their external risk ranges, which include political tensions and other delays around transportation. Well-functioning coordination means reducing downtime, which provides enormous operational resilience for the entire organization during peak trading periods.

6. Stock Audit and Reconciliation

The stock audit and reconciliation against the inventory are done to see whether the physical stock numbers tally with electronic records. Theft, spoilage, misplaced inventory, and entry errors in the inventory system should surface in audit results. There may be audits through weekly and monthly cycle counts, or once a year through a total inventory audit. All discrepancies will be reconciled in the inventory management system, and corrective actions will be taken. Consistent stock audits will enhance accuracy, support legal compliance, and facilitate better financial reporting.

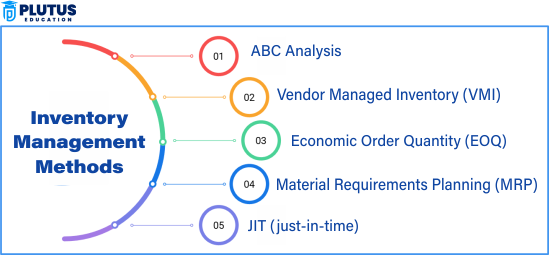

Inventory Management Methods

Different inventory management methods will therefore allow companies to optimize their inventories depending on the industry and size of the companies. Such methods guarantee that the appropriate stocks are available at the time of need with little cash tied up in inventories.

ABC Analysis

ABC analysis divides the inventory into three value consumption rate categories: A, B, and C. A consists of high-value items that are rarely sold. Their consumption or purchases must be monitored closely. B are those with medium values and turnovers among their types; they require intermittent tracking. C items involve low value and high turnover, thus do not need any of their kind to be paid attention to. This classification allows businesses to concentrate on the most impacted items and thus maximize resource utilization overall.

Just-in-Time (JIT)

Just-in-Time (JIT) inventory system is the reception of goods only when needed. In this way, the holding costs are minimized and wastage reduced. The most required features of JIT are accurate demand forecasts and reliable suppliers. Warehouse cost reductions and savings in money tied up in stock are the main benefits of this system. Most critical is that if there is just one delay in the supply chain, the customer would immediately feel it.

Economic Order Quantity (EOQ)

It determines the order quantity that would minimize total inventory costs. It balances ordering costs, such as procurement, and holding costs, such as storage. From EOQ calculations, a business will know how much to place on order and when, thus ensuring smooth operational efficiency and cost savings. Most effective for small and medium enterprises to optimize inventory without requiring sophisticated tools.

FIFO and LIFO

According to FIFO (First-In, First-Out), the older stock is sold first. FIFO is, however, effective for perishable items, such as food or medicine. LIFO (Last-In, First-Out), on the other hand, uses the newest stock first and is best applicable to industries that are volatile in prices. Both methods affect the cost of goods sold and taxation. Financial reporting is affected by the choice of FIFO or LIFO.

Types of Inventory Management

Many forms of inventory management depend on the organization’s size, complexity, and operational needs. Each inventory type provides a different level of control and accuracy.

Perpetual Inventory Management

Forever and ever, a line is drawn beyond which no party may enter into a state of perpetual dissolution. Inventory control systems in the approved list provide real-time control measures for tracking stocks, using bar code or RFID scanners. In most cases, inventory systems modify the quantity pafterevery sale or when goods are replenished. This is applicable in retail chains and e-commerce platforms. The system reduces errors, provides faster visibility, and increases customer satisfaction due to speedier fulfillment.

Periodic Inventory Management

Occasionally (a week, a month, a year), a manual stock count is carried out for inventory. This is far more costly than merely allowing discrepancies to arise between what has been recorded and what is present in reality. Most of these methods suit small-scale businesses or businesses with limited product lines. Although considerably less accurate, this method allows for the management of resources where automation cannot be applied appropriately.

Manual Inventory Management

Manual inventory management is a method wherein stock information is simply maintained in registers and spreadsheets. It has numerous pitfalls, and the process is very slow, hence prone wtohuman errors. However, this solution exists for micro-businesses at the cheapest possible cost. Discipline and frequent auditing of data must be embraced to maintain accuracy.

Automated Inventory Management

Automated inventory management systems comprise both software and artificial intelligence for stock management. Its functionality includes forecasting demand, automatic reordering, and integration with sales. Automation cuts down human interaction, speeds things up, and reduces the margin for error. These systems ensure rapid response to market demand while making operations scalable.

Inventory Management Advantages

Inventory management contributes to the profitability and satisfaction of its customers. It strives to synchronize stock levels with demand to eliminate excessive costs.

- Reduction of Storage Cost: Adequate inventory planning means minimal use of big warehouses and expenses with unsold goods. With the removal of excess stock, space and funds can be made available for reinvestment into productive ventures. With correct inventory management, finances will also be spared in the event of perishables.

- More Customer Satisfaction: Products are promptly picked for getting orders, leading to no delays. This kind of service helps build trust, leading to product purchases again. Accurate inventory also means precise tracking and fast response to customer inquiries.

- Better Financial Management: Companies do not tie up working capital in unsold stock. Cash flow is stabilized by regulating purchases according to actual demand. Accurate inventory information gives rise to better forecasting for finances and budgeting accuracy.

- Enhanced Productivity: The entire lineup of processes will move stock more quickly, reduce mistakes, and enhance order fulfillment. The more it relies on its automated devices, the more powerful a system becomes with less human effort. Efficient warehouses and well-trained personnel can further contribute to productivity.

Inventory Management Problems

Inventory management provides advantages; however, the existence of these advantages along with the challenges will require urgent amelioration.

Stock Discrepancies

Stock mismatches and, in cases of false stock information, overstocking or stockout may be caused by theft, misplacement, or errors in entries. Regular audits and application of barcode systems go a long waytowardr maintaining accurate data and minimizing stock loss.

Demand Fluctuations

Radical changes in customer demand may result in unanticipated shortages or surpluses. Statistical data will help predictive analytics for effective forecasting. Seasonal changes are also considered factors when managing inventory cycles efficiently.

Supply Chain Disruptions

A delay in the supply of goods arises from a vendor issue or a global crisis affecting stock availability in the market. Companies must establish relationships with multiple vendors and keep safety stock. Supply chain resilience is necessary to ensure the continuity of a business.

High Holding Costs

A good holding can incur costs from rent, insurance, or spoilage due to excess inventory. Techniques such as EOQ and JIT help businesses keep inventory at optimal levels. But the monitoring has to be continuous for healthiness in turnover.

Inventory Management FAQs

Q1: What is the primary goal of inventory management?

To balance stock availability with customer demand while minimizing costs and waste.

Q2: How does JIT inventory benefit small businesses?

JIT minimizes storage costs and increases cash flow by ordering only when needed.

Q3: What is the role of an inventory management system?

It automates tracking, real-time updates of stock levels, and improves accuracy.

Q4: Why is FIFO the preferred method of choice for perishable goods?

FIFO sells old stock before new, reducing waste through expiry or obsolescence.

Q5: What are the common problems inventory management faces?

Stock discrepancies;,demand volatility, supply chain problems, and high holding costs.